Time and percussion fuze for Schneider

75mm field guns

|

Schneider time & percussion fuze.

It was composed by : body (1), core (3), time fuze

mechanism (7), top composition ring (9), bottom composition ring (2), cover

(5), screw (19) and percussion fuze mechanism (15). |

|

|

The body

(1) was made of aluminium and had a stem screwed into the shrapnel head.

The upper part of the stem was cylindrical in shape and supported the two

rings of the time mechanism, the bottom of them being

attached on a slot (20) of the stem cap. The interior of the stem was

bored and threaded to receive the core (3) of the fuze. The magazine (21) at

the bottom of the core was filled with fine grain black

powder and connected with the slots of the bottom ring by a horizontal channel

with a vertical hole, filled with a tubule of pressed black powder. |

|

|

The

external end of the channel was closed with a plug

(4). At the bottom the stem was closed with a bronze

cap (22) with a hole in the middle to transmit the fire. The

hole was closed by a copper plate. The

core (3) was made of bronze and contained

the time and the percussion mechanisms. It was screwed

in the stem and had a ring nut on the top to screw the fuze cap (5). On the inside it was divided in two stages by a bar. The

time fuze mechanism (7) was

contained in the upper level and was composed by

firing pin (6), percussion spring (7) and percussion cap (8), contained in a

copper box. The

top (9) and the bottom (2) composition rings were both of aluminium. The bottom ring was mobile and was housed in the stem cap, a broadcloth disc being placed

between them. A groove was formed in the under side

for the time composition of pressed black powder (10). The walls of the

groove were coated with red brass, to avoid that the

charge was in contact with the aluminium. At the beginning of the groove

there was a hole filled with a tubule of pressed black powder and a

horizontal vent hole (11) for the

passage of the gas when the fuze burnt. The

top ring was

fixed and lay on the bottom ring, a broadcloth disc being placed

between them. A groove was formed in the under side

for the time composition, with a hole (23), as in the bottom ring. That point

was connected with upper stage of the core by an inclined

channel of red brass (12), fixed in the stem of the fuze and filled with

black powder. That channel transmitted the fire from the percussion

cap to the upper part of the time mechanism. The percussion

fuze mechanism (15) was contained in the lower stage of the core and was

composed by : needle (13) screwed in the core bar; little safety spring (14);

firing pin (15), carrying the percussion cap (16) and having on the axis a

channel filled with a tubule of pressed black powder; retracting girdle (18);

great safety spring (17); two springy segments (24). The firing pin lay on a cardboard disc (25), supported by the stem

cap. The cap (5) was screwed on

the stem and along with the creep spring (19) caught

the bottom ring of the time fuze mechanism. A hole (26) was

drilled on it, to centre the fuze when the shrapnel was put into the

fuze setter. The cap was kept in place by a stirrup

spring, placed in the core of the fuze. Two plugs

(20a) were screwed on the external surface of the

stem cap and of the bottom ring of the time fuze mechanism

to join the fuze setter. The lower part of the bottom ring was graduated in

meters to be set by hand with the fuze wrench, according with the lines (T)

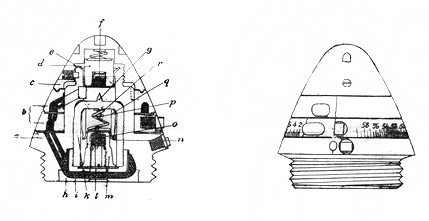

engraved on the stem cap. Krupp time & percussion fuze.

It was similar to the Schneider fuze, even if the internal arrangements were

slightly different. The body was made of aluminium and was

screwed into the shrapnel. It supported the graduated ring, where were

mounted the two rings of the time percussion mechanism and the fuze cap.

Inside the core was double-banked, the upper level containing the time

mechanism and the lower level the percussion mechanism. |

|

|

As

a whole, the Krupp shrapnel was composed by : – time mechanism : body with

graduated ring (a), time composition rings (b), cap (c), time pellet (d),

safety pillar (e), detonating cup (f), top needle (g), base plug (h), fine

grain black powder magazine (i); – percussion mechanism : holder

(k), mount (l), percussion pellet (m), safety pillar (n), detonating cup (o),

bottom needle (p), retracting girdle (q), spiral spring (r). |

|

|

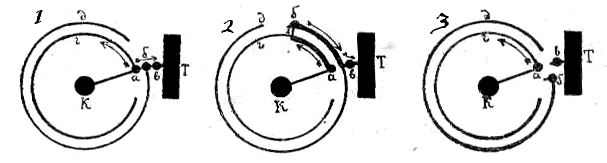

Operation of the time fuze.

When the gun was fired, the firing pin of the time

fire mechanism came back by inertia, compressed the percussion spring, strike

the ignitable substance in the percussion cup (8), which created a flash. The

flame was transmitted to the channel (12) and to the

powder of the top ring of the time fuze mechanism. Then it went through the

hole in the bottom ring, was transmitted to the

powder of the bottom ring, went through the hole in the stem cup and ignited

the fine grain powder of the stem magazine. Finally

it went through the central tube of the shrapnel, reached the powder chamber,

ignited the bursting charge the and the shrapnel burst. When

the top ring of the time fuze mechanism was set at 0, the vertical holes on

the fuze cap, on the top ring and on the bottom ring were

lined up and directly connected with the powder stored in the stem magazine.

Thus the shrapnel burst just after it left the

muzzle. Turning the bottom ring of the time fuze mechanism,

its hole moved away from the other two holes and thus the fire was

transmitted by the powder contained in the grooves of the two parts of the

time fuze mechanism : the more the top ring was turned (i.e. the more the

holes were distant), the more the transmission of fire took time. However the grooves of the time fuze rings were not

perfectly circular, but there was a sort of gap, called bridge. When the top

ring was turned so that the bridges were in front of

the holes (with the line on the graduated ring on T), the fire could not be

transmitted and the fuze was ready to be employed for percussion fire. Operation of the percussion fuze.

When the gun was fired, the retracting girdle of the

percussion mechanism dropped back and fell on the firing pin. Thus the great

safety spring was bent, but the retracting girdle could not went back, since

it was held on the firing pin by the springy segments :

the firing pin with percussion cap was then kept away from the needle only by

the little safety spring. When the shrapnel hit the target, the impact caused

the firing pin and the retracting girdle to snap up against the percussion

cap, after compressing the little safety spring. The ignitable substance in

the percussion cup (16), created a flash, the flame was transmitted to the

central tube of the shrapnel by the hole in the firing pin, reached the

powder chamber, ignited the bursting charge and the shrapnel burst. |

|

|

1. Position of the rings with

fuze set at 0 2. Position of the rings with

fuze set for time firing 3. Position of the rings with fuze set for percussion

firing |

|

|

К fuze toggle Т fuze cap with its hole в |

г

top ring with its hole а д

bottom ring with its hole б |

|

T&P Fuze |